Location

Municipality of Dugi Rat is located on the coast of the eastern Adriatic, approximately 15 kilometers southeast from Split, and 5 kilometers west of Omiš. The municipality of Dugi Rat includes Jesenice, Dugi Rat and Duće with more than 7000 residents mostly oriented towards tourism. Significant economic development occurred in the 20th century thanks to „Tvornica“ (Croatian for factory), a factory for the production of carbide and cyanamide, artificial fertilizer, in Dugi Rat. Tvornica was located south of Dugi Rat, on the cape of Dugi Rat on more than 180 000 m2.

History

The history of Dugi Rat is inseparable from the history of Tvornica which produced carbide and cyanamide. Before the construction of Tvornica, the area of Dugi Rat was primarily used for vineyards by the inhabitants of Jesenice, about 4 kilometers to the west. This was a consequence of the French wine industry being devasted by phylloxera in the second half of the 19th century. However, as the French wine industry began to recover at the end of the 19th century, the demand for dalmatian wine began to fall. Foretelling the possible catastrophe, don Frane Ivanišević, a notable inhabitant and politician from Jesenice, convinced his community to sell the vineyards on Dugi Rat for the development of Tvornica, arguing that the factory will provide jobs and education for their children. This turned out to be a good move – for the next one hundred years.

The land on Dugi Rat was purchased by the Italian association called SUFID, Italian for Societa per utilizzazione delle forze idrauliche della Dalmazia or The society for use of hydropower in Dalmatia. SUFID constructed a hydroelectric plant in Kraljevac above Omiš in 1912. to supply electricity to Tvornica which was constructed in 1914. Tvornica was a factory to produce carbide and cyanamide and it was the second such plant SUFID built, with another being in Crnica near Šibenik. The newly built factory on Dugi Rat had six furnaces that operated on the temperature of 3500°C – 4000°C in which a mixture of lime and charcoal was transformed into carbide. Milled carbide would then be exposed to nitrogen to get cyanamide, an artificial fertilizer. The daily production was around eighty tons, with a yearly output of about 25 000 tons of cyanamide.

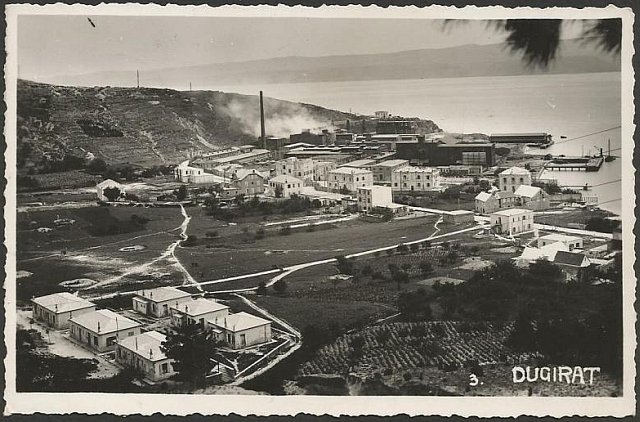

Carbide and cyanamide Factory in Dugi Rat, around 1915. – Source: Technical encyclopedia of Croatia

Cyanamide was further milled in Crna kuća which was located next to the dormitories, and the fine black cyanamide dust covered workers and was dispersed by wind into the environment. From the dormitories Dugi Rat further developed as a settlement. With SUFID losing the concession in 1929. to French investors, Tvornica was officially renamed to „La Dalmatienne“ (meaning a female dalmatian) and, despite the economical crisis that followed, large investments into the community of Dugi Rat were made with the building of a cinema, sport courts, bowling alleys, church and even a hospital thanks to the union. Simultaneously Tvornica was expanded with a port for ships up to 30 000 tons and two cranes, large purchases of land, a new furnace to produce crude iron, modification of an existing furnace for the production of ferroalloys and also with a construction of a gas pipeline both for the factory and for the community.

During 2nd World War Tvornica was overtaken by the Italians, and shortly after NDH (Croatian for Nezavisna država Hrvatska, English for Independent state of Croatia), a fascist puppet state of Nazi Germany. Even Germans shortly operated in Tvornica, while also setting up mines to destroy it in case of retreat. However, thanks to the brave work of local men the mines were deactivated and Tvornica lived through the war. After the war Tvornica was nationalized and continues with the production of carbide, cyanamide and ferroalloys, but without the furnace for crude iron. In 1952. waterworks delivering fresh water from Suhi Potok was completed also thanks to Tvornica, while in 1953. the electricity, so far used for free by the community, started being charged for. In the seventies Tvornica switches entirely to the production of ferroalloys because of a large competition in artificial fertilizer production and because of developments in the petrochemical industry which made carbide and cyanamide lose on value. Until the Homeland war in 1990., Tvornica expanded its production from ferroalloys to electromechanical devices in cooperation with company Iskra from Kranj and to liquid gas with Montkemija from Zaprešić.

Postcard from Dugi Rat – Source: Archives of dugirat.com

During the Homeland war in the first half of the 1990s Tvornica almost stops with production due to uncertainty in the electric energy supply. At the end of the war only one furnace remained operational and with great difficulty as the facility was unmaintained. Soon after Tvornica declares bankruptcy and in 2003. the liquidator starts with Tvornica’s deconstruction. The intention was to repurpose the Tvornica’s land for the needs of a new industry – tourism. However, due to the financial crisis at the end of the 2000s the plans are never fulfilled, and so the location of former Tvornica remains empty, polluted, and unused.

Problem

After the closing of Tvornica, more than 1 670 000 m3 of waste material remained – mostly slag, construction waste, dust, and other waste. Most of the waste products during production were disposed of in the sea and are now parts of the coast as well as being exposed to the sea and the environment. Ecological studies performed so far were not conclusive or have methodological lacking. Further research is advised on various locations in Tvornica in order to determine the full extent of metal oxides and heavy metal presence in the environment as well as radioactivity. Detailed research would also provide a plan for remediation of the Tvornica environment, allowing for the future repurpose of the land.